Industrial yarns and strapping

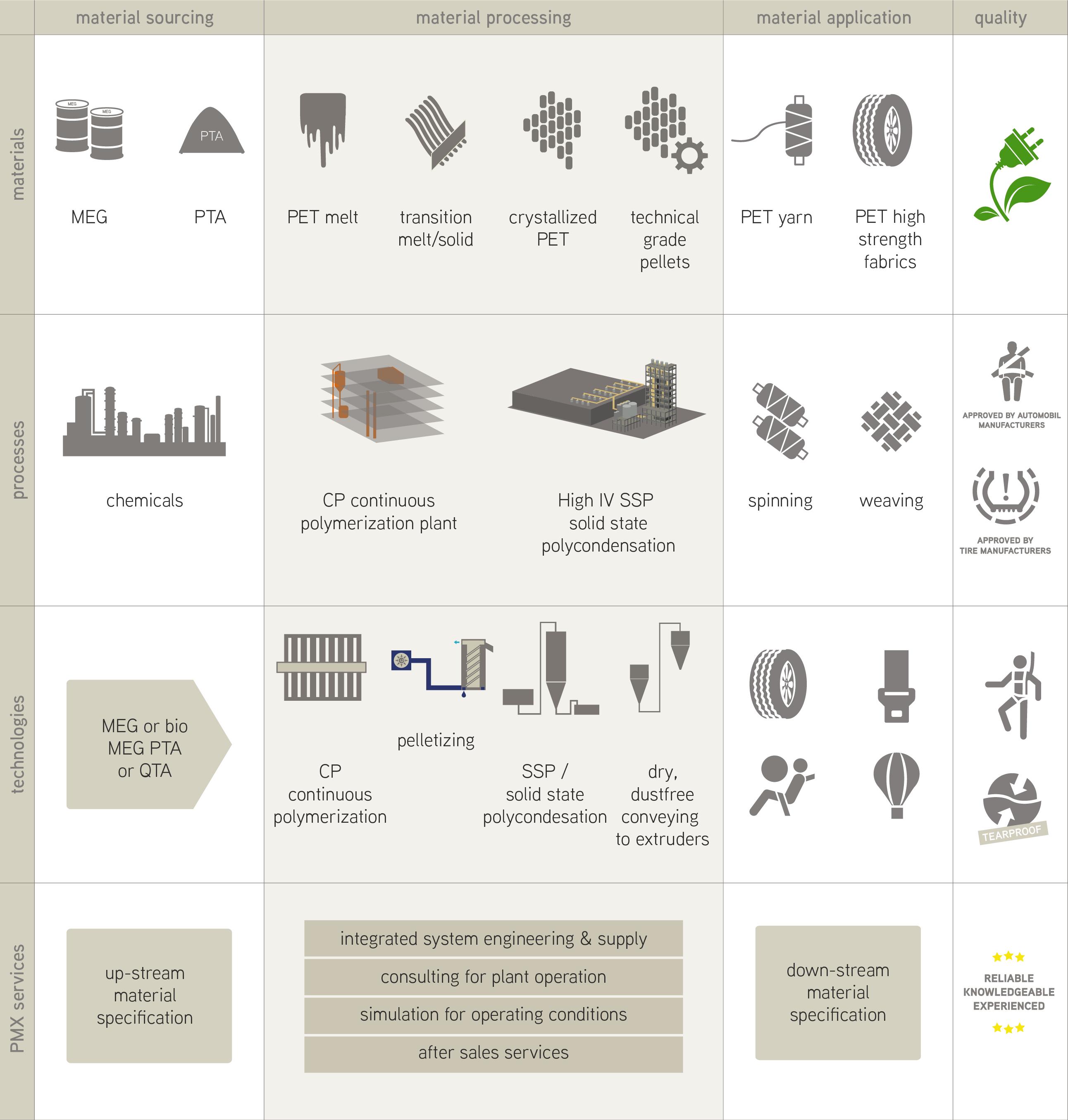

POLYMETRIX SSP process technology ist use to refine the PET pellets as an intermediate product of the CP plant into PET pellets with high viscosity. The SSP process can increase viscosity by up to 0.5 dl/g. At the same time, the SSP process reduces the carboxyl end groups inside the PET pellets and reduces the moisture in the product to a very low level.

The PET pellets can be cooled and packaged for further processing elsewhere.

To save costs for logistics and energy, the hot PET pellets are ideally conveyed directly from the SSP plant to the spinning extruders.

The refined pellets are conveyed to the spinning extruders by dense phase conveying at slow speed and minimum dust formation under dry air or nitrogen. This enables yarns of the highest quality to be obtained at maximum spinning mill output.

PET SSP leaN - floor mounted design

Pneumatic pellet and flakes conveying